75 Years of Elevator Guide Rail Excellence

World market champion for precision-engineered guide rails. Trusted by the industry's leading manufacturers.

A Legacy of Excellence

Since 1940s, leading innovation

Global manufacturing presence

Expert team worldwide

Sustainable growth

Precision Engineering

Engineered for Performance

Every guide rail is manufactured to exacting tolerances using advanced cold drawing and precision machining processes. Our T-section profiles ensure optimal elevator car guidance and stability across all building heights.

- •Zero Defect Quality: Multi-point inspection guarantees dimensional accuracy

- •Multi-Standard Compliance: ISO, ASME, JIS, CSA, ANSI certified

- •Custom Configurations: Tailored bracket spacing and mounting solutions

Global Service

Worldwide Support & Technical Excellence

With manufacturing facilities in 9 countries across 4 continents, Monteferro delivers local expertise backed by global consistency. Our worldwide network ensures rapid response times, technical collaboration, and seamless logistics for projects of any scale.

- •9 Countries, 4 Continents: Local manufacturing with global quality standards

- •Technical Partnership: Engineering collaboration and custom solution development

- •Rapid Delivery: Distributed facilities for optimized logistics worldwide

Guide Rails

Precision-engineered guide rails from 3-50 kg/m for all elevator applications

- •3-50 kg/m weight range

- •Cold drawn & machined

- •Residential to supertall

- •Multi-standard compliant

Fishplates

Complete range of guide rail connection systems from standard to seismic

- •Standard & Double Thick

- •Seismic Zone 3 compliant

- •T-Plates available

- •40+ models

Clips & Fastening

Guide rail clamping systems for thermal expansion and rigid mounting

- •Sliding & Forged clips

- •High-rise applications

- •Thermal expansion control

- •18+ models

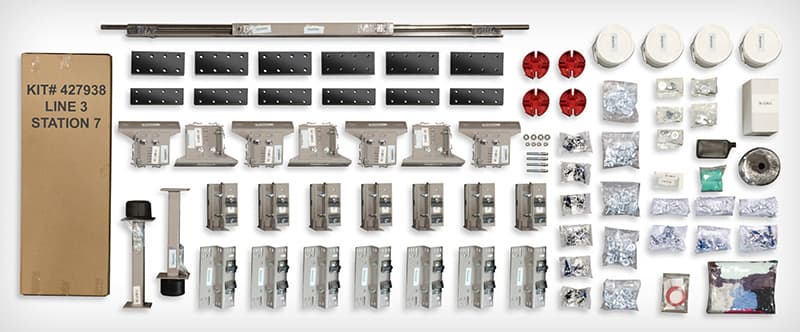

Complete Hoistway System

Beyond individual components, Monteferro delivers complete integrated hoistway solutions combining guide rails, fishplates, clips, and brackets into optimized systems designed for seamless installation and long-term performance.

Integrated Design

All components engineered to work together as a complete system for optimal performance

Simplified Installation

Pre-configured systems reduce installation time and complexity on site

Full Support

Technical consultation and engineering support throughout project lifecycle

Commitment to Sustainability

At Monteferro, sustainability is integral to our manufacturing philosophy. We continuously invest in technologies and processes that reduce environmental impact while maintaining the highest quality standards. Our commitment extends from material selection to production efficiency, creating products that serve the future of vertical transportation responsibly.

Our Initiatives

- Material Optimization: Advanced processes that minimize waste

- Energy Efficiency: Reduced consumption and emissions

- Sustainable Innovation: Lighter, efficient products like Light Rails

- Long-Term Value: Durability reduces replacement cycles

Trusted for the World's Most Iconic Projects

Burj Khalifa

World's tallest building reaching 828 meters. Our guide rails enable reliable vertical transportation in this architectural marvel.

Shanghai Tower

One of the world's tallest buildings reaching 632 meters. Monteferro guide rails support high-speed elevators in this supertall skyscraper.

The Shard

Western Europe's tallest building at 310 meters. Our precision guide rails power vertical transportation in this iconic glass pyramid.

One World Trade Center

The tallest building in the Western Hemisphere at 541 meters. Monteferro guide rails ensure safe, reliable elevator operation.